Dairy farming is a cornerstone of the agricultural sector and is critical to productivity and sustainability. In recent years, technological advances and innovative solutions have...

With its trustworthy technology and superior engineering, SETUAY offers world-class quality, reliability and efficiency in milk and water cooling systems.

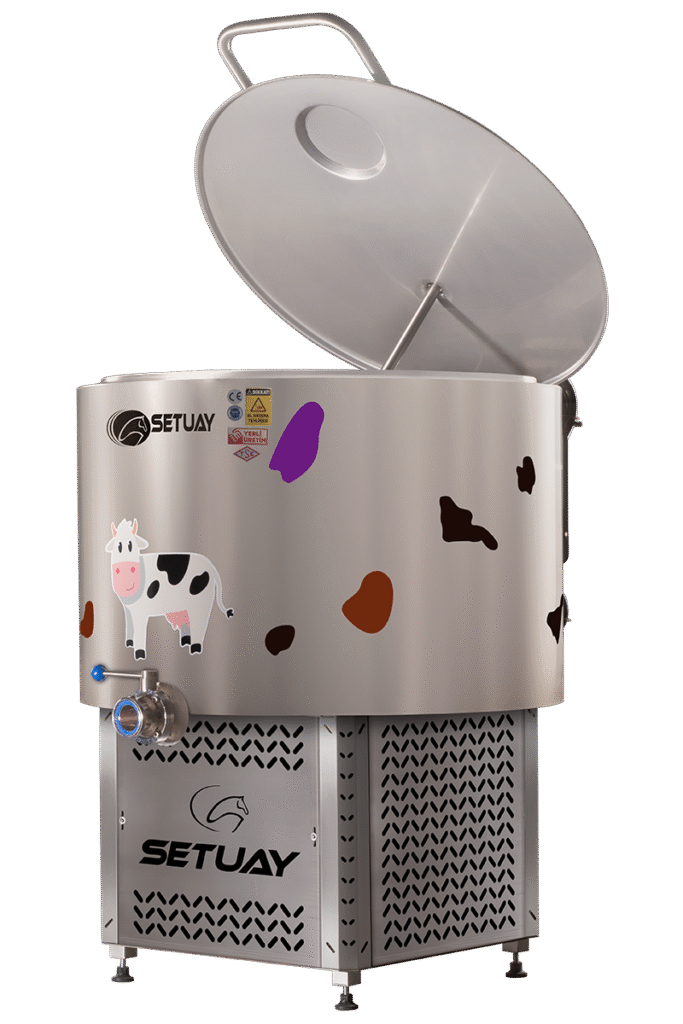

SETUAY milk and water cooling systems are designed with a focus on high quality, reliable performance, and longevity. Our products stand out in the industry with their stainless steel construction, laser-welded evaporator technology, and high insulation capacity.

Possible with SETUAY

SETUAY delivers quality, reliability, and efficiency in milk and water cooling systems at global standards through its innovative technology and superior engineering.

Prioritizing customer satisfaction since its inception, SETUAY has gained an international brand identity by exporting to more than 44 countries. Thanks to its high technology, specialized laser-welded production, and expert staff, it completes all its projects on time and above expectations.

For product and service details, you can contact us via our website or by phone.

Contact us for innovative solutions, and we'll respond to your questions quickly. We are customer-friendly and always easy to understand.

Contact us immediately to get answers to your questions and receive prompt support.

Why Choose Us?

SETUAY offers reliability, quality, and efficiency in milk and water cooling systems with its innovative technology and experienced staff.

SETUAY’s Global Partnerships: We share efficiency and quality with our milk cooling tanks in 44+ countries! Build the future of farms with partnerships that meet global standards.

From Bulgaria to Germany, from the Taiwan to Algeria, from the United Kingdom to all corners of the world…

With its durability, engineering, and innovative production approach, it delivers the same consistency across every region.

Dairy farming is a cornerstone of the agricultural sector and is critical to productivity and sustainability. In recent years, technological advances and innovative solutions have...

In recent years, technological advances in milk production and processing have led to an increase in demand for milk cooling tanks. This increase is directly...

What is a Milk Tank and What is It Not? Innovative Approaches in Modern Milk Cooling Technologies… Milk, by its nature, is a perishable food...

Global partnership in milk cooling in 44+ countries!

The undisputed leader in milk cooling in over 44 countries! We take quality and efficiency to the highest level with our innovative tanks. The future of farms is with us!

Catch the Future with SETUAY!

We empower your farms with our milk cooling tanks and innovative solutions! Subscribe to our email newsletter to be the first to hear about SETUAY’s latest technologies, campaigns, and global successes. Join now and get to know the leading brand in efficiency!

SETUAY, Turkey’s leading brand, adds value to your farms with milk cooling tanks, and we build the future together!

© 2026 setuay.com.tr/en